TrioWeld and Engineering Services (PTY)Ltd

If you have a project requiring specialisation, particularly in welding combined with quality and a high degree of individual commitment please contact the Company.

About

| TrioWeld and Engineering Services was originally established in 1997 as a family-owned business and in 2017 changed the name of the business and, as the name suggests undertaking welding of a specialized nature with demanding quality standards. Jan Steenkamp, the original founder of Trio, has over 40 years’ experience in the welding industry, accumulated over a wide range of industries and products. |

| The Company was founded on a commitment to quality and to achieve standards which meet and, wherever possible exceed client’s expectations. This commitment has always been in place and continues today. Most of the larger projects undertaken by the company require the involvement of an independent inspection authority. The Company works with several such authorities which are either specified by or agreed with the client. The defect rates achieved by the company are exceptionally low, in line with the commitment to quality. The Company is moving to the establishment of a formal quality system for the larger projects which will complement the |

Services

SERVICES:

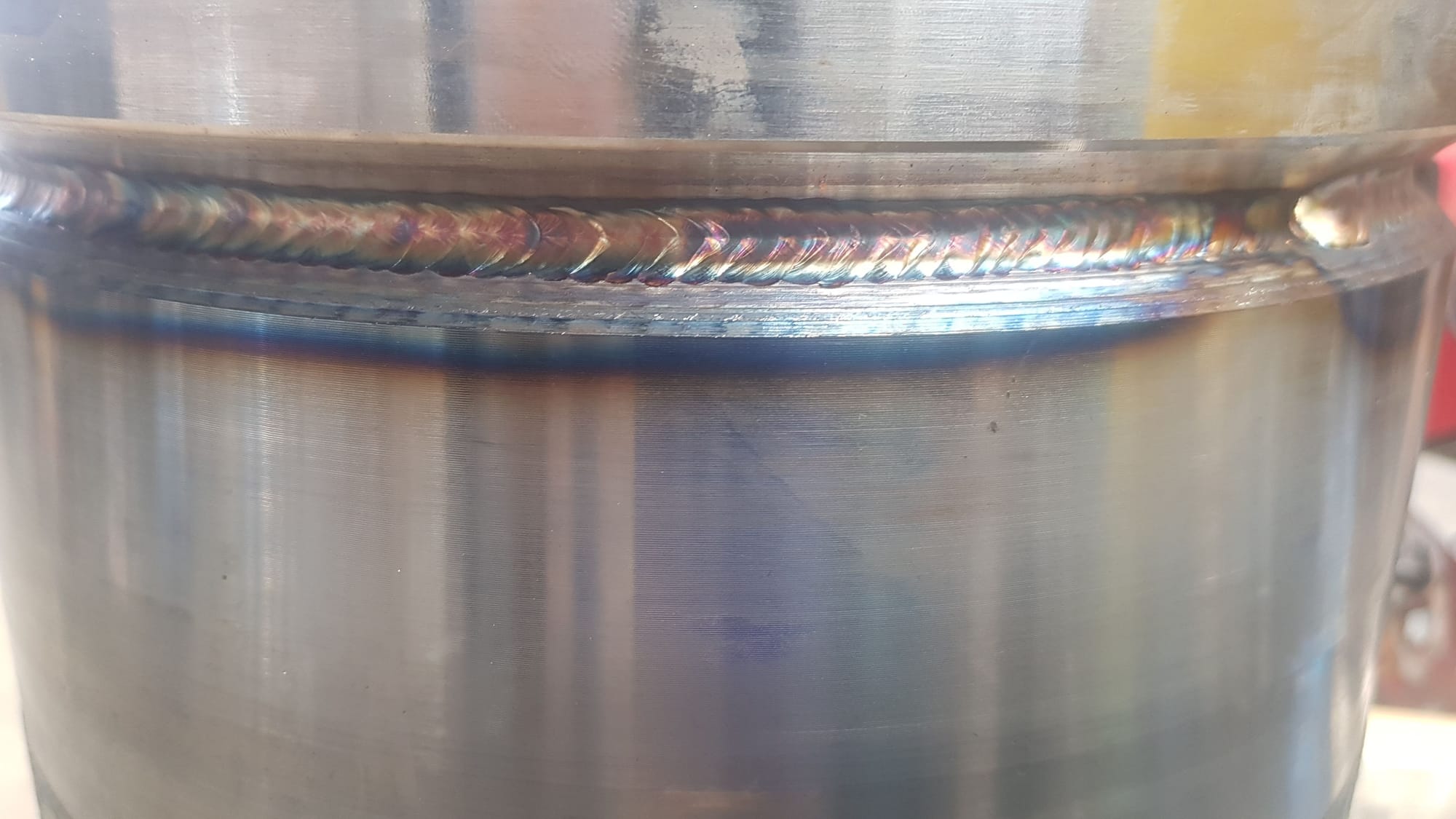

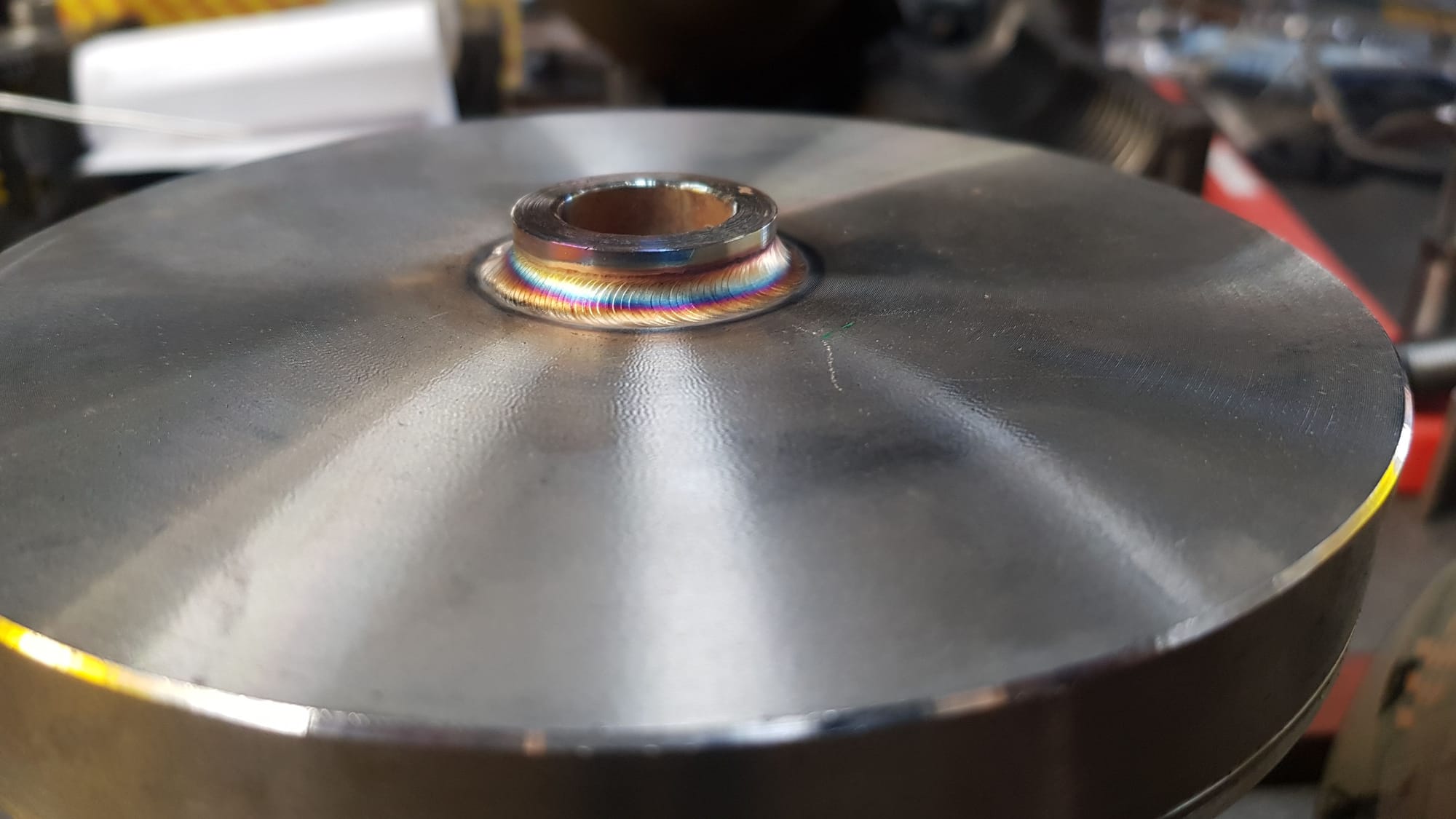

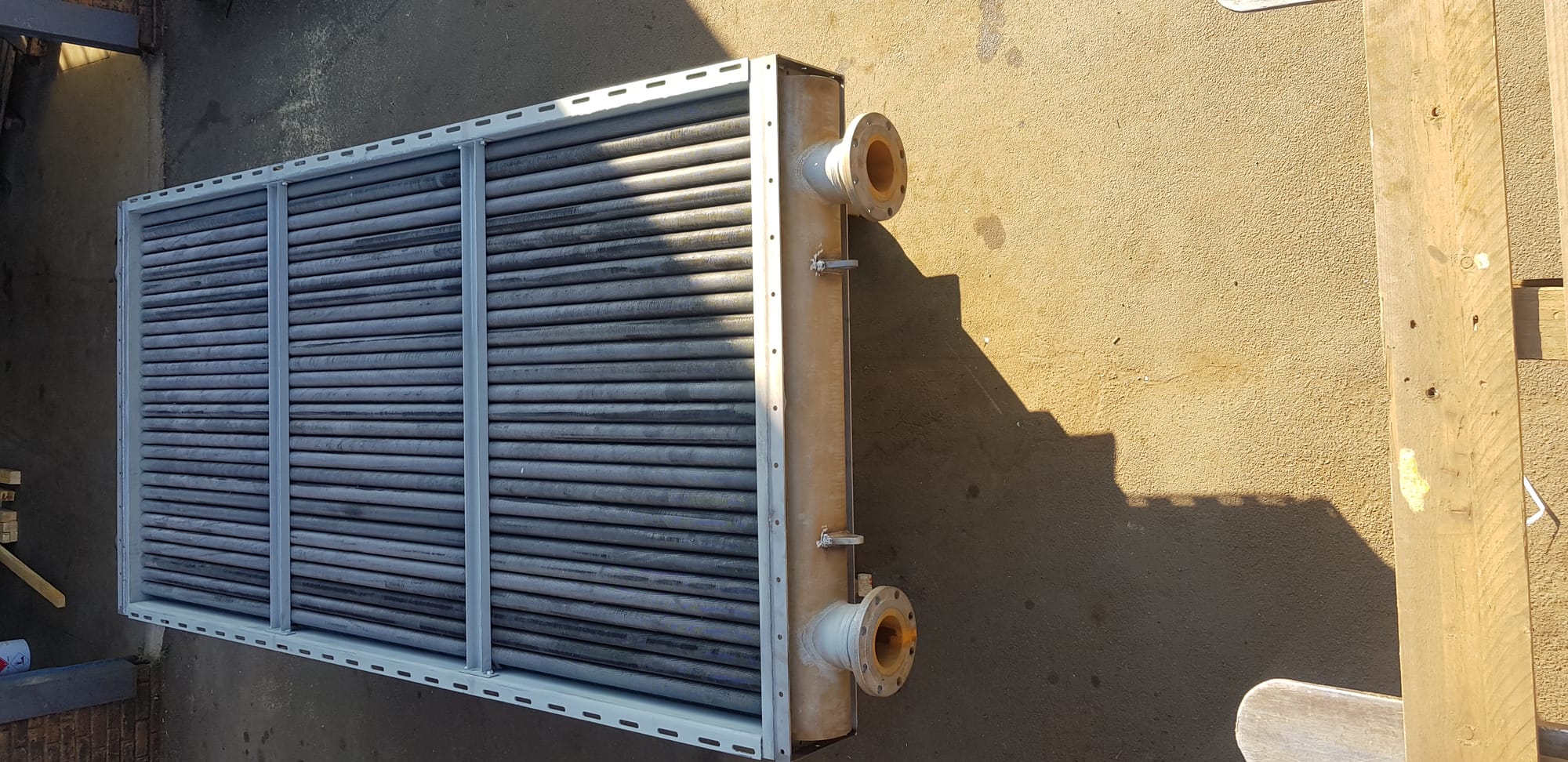

The core competence of the company still remains welding but as the company has continued it has added further associated engineering activities in order to service customer needs, including: conventional turning and milling, CNC turning /milling and assistance with engineering design and solid modelling CAD. The company has also progressed to successfully undertaking significant manufacturing projects. Welding Capabilities. The principal welding processes used by the company are TIG, MIG and MMA The Company welds a large range of materials and the following is a broad outline of the capabilities. A wide range of carbon and carbon alloy steels A wide range of Stainless Steels A wide range of Aluminum Alloys A wide range of other materials for example:- Aluminum Bronze, Cast Iron, Magnesium, Copper and Titanium. Hard facing is also done. The standards most commonly worked to are AWS, ASME and PD5500. The Company has a range of qualifications but if additional qualifications are required the Company will collaborate were practical in obtaining the requisite qualifications. The Company’s wide range of welding techniques, combined with the ability to work with a wide range of materials, has enabled it to render specialist services on products ranging from light through to heavy engineering. Whilst much of the welding undertaken is done in the workshop, the company also works extensively on sites undertaking a wide variety of repairs. Installations of either new or replacement equipment are undertaken. Many of the sites require positional welding in difficult conditions and the high level of welding competence of Trio delivers quality results in such circumstances.

Contact

- Apex, Benoni, South Africa

- 56 Detroit Street Unit 1a

- +27-11 420 2155 - TrioWeld and Engineering Services (PTY)Ltd

- +27-84 740 8912 - Geem Steenkamp

- +27-83 390 3807 - Jan Steenkamp

- geems@telkomsa.net

- Mon - Thurs : 07:30 - 16:30 Friday : 07:30 - 14:00